“Disassemble less and see more.” This is our mantra when it comes to performing a video bore scope inspection on your electrical generator.

By simply removing the hand hole manway covers on each end of the generator, we can inspect deep into most areas of the generator including; under the retaining ring, in the gas gap ( including on hydrogen cooled units ), the outside diameter of the rotor from the gas gap, the inner stator basket ( including the step iron and press finger areas, and areas of the outer stator basket.

In all areas we look for indications of looseness and other signs of damage such as greasing, dusting, broken supports, damage ties, movement in the blocking, and other indications. Often, we can insert a videoscope through the fan blade gaps to further reduce the need for disassembly. By reducing disassembly, electrical generator units can be inspected during short outage periods, allowing for better maintenance planning during longer outages.

Disassembly is generally limited to the manway doors and possibly the outer end shield if the unit has no manway doors. We have experience on most manufacturer units including GE, Alstom, Toshiba and Westinghouse generators.

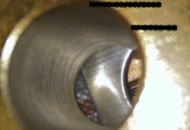

Areas viewed include: Under the retaining ring to view the coils and turns for indications of loose insulation, discoloration, warping, elongation and other indications, including the turn to turn connections and coil cross tie jumpers.

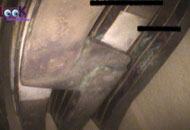

In the stator basket, we use the videoscope to inspect for greasing, discoloration, dusting, loose banding and other indications, viewing the stator windings, support brackets, step iron and press finger areas. On the outside of the stator basket the stator windings are inspected for signs of looseness, the key bolts can be viewed for indications of movement, water cooling components for indications along with support brackets and parallel rings.

FME close out inspections can be performed when work is completed before final disassembly. With access to the side panels, areas of the back iron can also be viewed for spark erosion and other indications.

If you have generator inspection applications that you would like to discuss, contact us now at 877-915-5665, we are happy to help.

Electric Generator damaged coil to coil jumper

Electric Generator damaged coil to coil jumper

Electric generator, greasing at the step iron

Electric generator dusting on inner stator bars

Electric generator spark erosion

Electric generator rotor slot migration cooling hole misalignment

Electric generator spark erosion on back iron key bar

Electric generator greasing near the press fingers

Electric generator pole to pole connector